Transmission of Electric Power by Sea

The article contains the description of cables used in the broadly understood industry of submarine cables, and which are offered by TFKable Group. It presents types of cables used together with the purpose of those cables and differences in their construction and design. Submarine or Subsea Cables are used for transmission of power or control electricity by sea and have diverse constructions as a consequence of their application. Products can be broadly categorised into SPC1 (subsea power cables) or Intra-Array Cables2, through to SPU cables (subsea production umbilical)3 or IWOCS (Intervention Workover Control System)4 dependent on the extent to which power or control functions are needed to connect subsea infrastructure. Large amounts of power in the hundreds to thousands of Megawatts and transmitted using so called INTERCONNECTOR5 or Grid-Link cables that connect islands and countries with each other over larger distances in the range of tens or hundreds for kilometres.

The production processes used in the construction of subsea cables must always be very precise and repeatable and ensure high quality of workmanship. Connections of individual lengths made during production process, so called ‘FACTORY-JOINTS6 are produced with very high attention to detail in order to ensure repeatable quality, which in turn results in high reliability of long lengths of subsea cables during their operation.

Due to environmental conditions in which subsea cables operate, each failure results in great costs related to the loss of power transmission as well as the complicated repair procedures in the harsh offshore environments out to sea. However, constantly growing demand for this type of cables and increased interest of Poland in the development of offshore renewable energy makes this industry very attractive for energy infrastructure developers and cable manufacturers alike.

1 SPC cables (subsea power cables) are power cables usually transmitting electricity between oil platforms or an oil platform and land.

2 Intra-Array Cables – cables used for transmitting electricity between off-shore wind turbines

3 SPU (subsea production umbilical) cables- so called ‘umbilical cables’ are cables used for supplying electricity and fluids, such as water, oil; as well as transmitting data and information with the use of fibre optics installed in the, or any other necessary consumables, for example to oil platforms

4 IWOCS (Intervention Workover Control System) –systems allowing for quick restoration of operation, supply of power or any other utilities in the event of failure of systems – subsea systems. They may also be used for temporary supply of power to devices installed on the seabed.

5 INTERCONNECTOR – HV power cable, usually at least 150kV, used for power transmission by sea over very long distance.

6 FACTORY-JOINT – connection between two lengths of single cores of power cables made already during production of sub-sea cables by recreation of each layer of cable design.

INTRODUCTION

The first ever underwater cable used for power transmission was installed in the Isar River in Bavaria in 1811. Since that time underwater cables, especially subsea cables, have evolved considerably due to technological development and changes in design, continuously increasing their capabilities with respect to voltage levels, load capacities and lengths. From the very beginning, subsea cables production has been associated with the need to use sealing, which functioned as protection against negative impact of water and moisture on insulation properties of cables. It is this feature along with additional mechanical protection (armouring) that made sub-sea cables different from widely used land cables.

Fig. 1. Bydgoszcz cable factory in the 1920s

TELE-FONIKA Kable S.A., hereinafter referred to as TFKable Group, began its story with subsea cables in 2008. It was in that year when cooperation began, which resulted in commencement of production of single-core power cables in TFK factory in Bydgoszcz for a British company JDR Cable Systems. From these high quality single-core lengths sub-sea cables were then assembled into 3-core completed cables at the JDR factory in Great Britain. The history of TFKable group, however, is a little bit longer. TELE-FONIKA Kable S.C. company was founded in 1992, as a result of which a modern plant manufacturing telecommunications copper cables, computer and optical cables was constructed in Myslenice. Favourable market situation, excellent quality and leading position on the Polish market allowed for further development of the company. And thus, in 1999, Krakow Cable Factory (Krakowska Fabryka Kabli SA – KFK) was incorporated into the company. In 2001 a modern, robotised Krakow-Biezanow factory started operation. Later that year majority stake of ELEKTRIM Kable S.A Company was purchased. Due to acquisition of the entire share package of ELEKTRIM Kable S.A a new entity TELE-FONIKA Kable S.A. was formed. As a result of this acquisition, TFKable Group obtained Bydgoszcz Cable Factory (Bydgoska Fabryka Kabli – BFK) constructed in 1923. In the following years the Group grew even more by purchasing such factories as: Enej-Eletrokabel Plant in Chernihiv in Ukraine, Waste Recycling Plant in Bukowno, and Zaječar cable factory in Serbia. In 2017, due to acquisition of JDR Cable Systems (Holdings), hereinafter referred to as JDR Ltd., TFKable Group added to its assets two production plants located in Great Britain. As a result, TFKable Group joined an elite group of direct suppliers of solutions for power transmission by sea

Fig.2. Bydgoszcz Manufacturing Plant

Cable used for transmission of electric power by sea.

JDR is a global supplier of subsea solutions for oil and gas industry, as well as renewable energy. The company has been involved in specialist cables, hoses and umbilicals since its early origin over 50 years ago. In the past 20 years it has been successfully growing its power and control product capabilities thanks to its technical knowledge and credibility. JDR’s portfolio grows from year to year, and the company engages in newer and more technologically advanced projects in the field of designing, manufacturing, delivery, installation and service works for offshore energy developers and operators.

Fig. 3. Portfolio of subsea cables offered by JDR, depending on their application. From right: SPC cable, two types of Umbilical cables, IWOC system

Subsea Power Cables (SPC) – a group of AC power cables that are usually used to transmit electric power between platforms or wind farms located in the sea and between platform and land. This group also includes so-called Intra-Array cables designed to directly connect wind turbines with each other and back to an offshore subs-station platform. A typical Subsea power cable consists of three cores containing water-blocked conductors and XLPE insulation. The three insulated cores are laid up together with an additional optical fibre, and secured against external forces by a layer of bitumen tapes, armour made of steel wires and protective outer layer. The cores, which are manufactured at the TFKable plant in Bydgoszcz, and later on transferred to factory in Hartlepool as per the production process, have a unique solution for water-blocking (sealing) conductors. This solution guarantees resistance to penetration of sea water at pressure of min. 5 bar, which corresponds to the depth of approximately 50m.

Due to limitations resulting from production capacities with respect to the continuous length of single core that can be produced, a common practice during production of long lengths of subsea cables is to connect single cores during the stage of laying-up with the use of the a FACTORY FLEXIBLE JOINT method. As far as subsea cables are concerned, a special method of connecting individual lengths is necessary, which guarantees similar strength as in the original cable and retain a very high quality of insulation through the joint. Furthermore, due to the nature of the production process, what is also crucial is to maintain similar diameter at the point of connection as in the original length of the cable, so as to allow the cable to be pulled through subsequent elements of production lines.

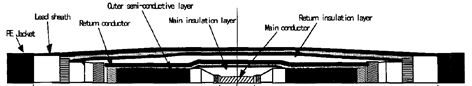

Fig. 4. FACTORY-JOINT for cable DC 120kV sample drawing

The FACTORY-JOINT connection consists in connecting conductors with the use of specially designed welding devices, reconstruction of semi-conductive inner screen, insulation layer, and semi-conductive outer screen by manual application of appropriate tapes and then cross-linking these layers, and recreating the neutral conductor (screen) and the outer sheath. The jointing process can take time to make such a connection, and it also requires very precise and accurate equipment and qualified personnel. What is also essential is repeatability of the process, appropriate cleanliness and accuracy. Following extensive trials, training, equipment upgrades and continuous improvement of the equipment and the procedures, JDR and the TFKable Group now provide the type of high reliability FACTORY FLEXIBLE JOINTS essential for long-length submarine cable applications.

SPU (subsea production umbilical) cables – commonly known as umbilicals, are custom designed multi-line products delivering power and control depending on the specific needs of offshore consumers in the Oil and Gas sector. Depending on customer requirements they may simultaneously function as MV or LV power cables together with fluid transmission hoses or tubes, which are used for various media, such as oil, water or gas. Umbilicals are also used to provide data transfer and communications between subsea infrastructure, either with the use of optical fibre or any other copper conductor telecommunication cables. Depending on the application, umbilicals can incorporate steel or plastic tubes, cables and other materials in the laid-up bundle. Filler materials and bedding layers in the construction function as a re-inforced framework. Armouring made of steel wires acts as a reinforcement for the construction and the finished umbilical or cable includes an outer protective sheath. Materials of high quality, confirmed by numerous certificates, design experience, continuous improvement and attention to detail cement JDR’s position as a leader and a reliable supplier of these products, vital to the operation of offshore oil and gas systems.

IWOCS (Intervention Workover Control System) systems also use a specialist type of umbilical to enable the control of oil and gas valves on the seabed. IWOCS umbilicals typically consist of an electrical power or signal cables, hydraulic conduits and structural and mechanical elements. The IWOCS umblical in typically integrated into a winch system referred to as a ‘reeler’. The Reeler controls the pay-off and recovery of the IWOCS umbilical, allowing for easy deployment and retrieval. The system has connections for topsidie power and control and a custom engineer subsea termination connection that is remotely plugged into the well-head control system equipment located on the bottom of the sea.

IWOCS umblicals are used for several activities including the provision of temporary power and communications during the pre-drilling and well-completion phases. They are also used for controlling and monitoring of submarine equipment during installation works, or for performing maintenance and repair to subsea equipment.

IWOC systems provided by JDR are custom-engineered to be used in the most demanding conditions.

.jpg)

Fig. 5. JDR umbilical cables to be used in the IWOC systems

INTERCONNECTOR – The products are High Voltage (HV) power cables, usually 150kV or higher, used to transmit power by sea over long distances. The purpose of such cables is mainly to enable the easiest and the most economic possible method of power transmission between countries. This ensures security of power supply and has a significant impact on reducing price fluctuations, which in turn affects growth rates of economy of a given country.

Fig. 6. Iterconnector cables in Europe

The first commercial HVDC commercial cable was installed in 1954 in Sweden. It connected the island of Gotland with the mainland (voltage level amounted to 100kV, max. load of 20MW, length 90km). By 2017 total length of Interconnector cables increased to around 8000 km. Due to energy losses during transmission of power by AC power cables (caused by skin effect among other things), Interconnector cables are usually operated as DC systems . Transmission of power in the form of direct current is connected with the need to use inverter stations that constitute a significant share in the total cost of the transmission line. Nevertheless, energy losses in AC cables installed over large distance are much higher than the total cost of the whole DC system. Design of DC cables is not significantly different from cables transmitting AC current. The design of such cables has evolved in a similar way to HV land cables, i.e. the most crucial in both cases was switching from paper-oil insulation to the XLPE material used currently. It is the insulating material used for production of DC cables together with manufacturing aspects and so-called technological regime that constitute the main difference between DC and AC cables. Very high cleanliness of insulation, even at the molecular level, accuracy and stability of the process over the entire length of the produced section is the case of DC cables production an obligatory factor for obtaining high quality. Therefore, special XLPE materials are used for these cables and typically these require a much longer time for the so-called degassing process as part of cable manufacture. They are, in turn, modified in such a way as to generate as few by-products as possible during the process of curing (cross-linking)

Requirements of the Subsea Market

In addition to principal requirements resulting from standards, the offshore power industry has particularly high expectations with regards adequate quality assurance. Full production documentation, going beyond common practice and obligatory actions required by standards, is an indispensable part of products supplied to customers. Supervision over the production, factory acceptance tests and inspections, numerous audits and visits by inspectors hired by customers and investors are to ensure that production of subsea cables is realised with appropriate care and engagement.

Fig. 7. Insulation material handling in the clean room

The guarantee of the above based on appropriate documentation of the process in the form of digital data from each stage of production, check-lists, tests and all production parameters recorded at every minute of the process makes TFKable group a reliable and trustworthy partner.

To achieve such a high level of process control and to fulfil all customer requirements, state of the art machines with automatic control and measuring systems as well as appropriate infrastructure, trainings, procedures and instructions are necessary. X-Ray and ultrasonic systems that are used for continuous monitoring of cable construction parameters, or cleanrooms are good examples of that. The aforementioned cleanrooms have been designed in such a way as to meet very strict requirements of cleanliness classes in accordance with the ISO 14644 standard ‘Cleanrooms and associated controlled environments’.

Projects completed by TFKable Group

The TFKable Group has successfully completed more than 60 projects with regards renewable energy and oil and gas industries. The most important of these were: supplying cables for the two biggest offshore wind farms in the world – London Array (2011), Greater Gabbard (2009), and Hornsea 1 (2017); as well as currently realized deliveries for Formosa 1 and Hornsea 2 windfarms. JDR has also provided cables for such projects as: Meerwind, Nordsee One, Dudgeon, Galloper, Veja Mate, Rampion, Race Bank, Sandbanks, Beatrice, Hornsea One. In 2017, TELE-FONIKA Kable together JDR has expanded its portfolio by including to it HV subsea cables with a voltage of up to 66kV by providing subsea cables for projects Aberdeen Bay and East Anglia 1. By 2017, TFKable plant in Bydgoszcz had supplied over 7 thousand kilometres of subsea cores to JDR, which were then used in JDR plant in Hartlepool in Great Britain to produce and supply over 2 thousand kilometres of subsea cables.

Future of offshore energy

According to the WindEurope Association in several years about 30 percent of power should be generated from wind. WindEurope believes that in order for it to happen investments amounting to EUR 240 billion by 2030 are necessary. The TFKable group has been participated in more than 30 percent of the already completed and operational offshore wind farm projects. In the future, also in our country wind power may be a crucial part of so-called power mix. According to estimates of McKinsey & Company, if the wind farms of the planned capacity were actually constructed, value of Polish GDP could increase thanks to investments in the offshore sector even by PLN 66 billion. Furthermore, Polish market would generate approximately 77 thousand of additional jobs. It is also worth noting that according to experts from Polish Offshore Wind Energy Society, taking into account legal and formal conditions as well as technical and implementation aspects, it can be expected that the first offshore wind farms in Poland could start providing energy from sea to land around 2022. The first stage of realisation of these investments will be in the period of 2020-2025, whereas by 2030 construction and launching offshore wind farms with total capacity of even 6 GW will be possible.

The latest available analyses clearly show that the cost of construction of offshore windfarms is constantly decreasing. It has been made possible thanks to using new larger turbines with capacity of 8 MW. As a result, voltage of cables connecting turbines has increased from 33 kV to 66 kV, whereas voltage of export cables has increased from 132kV to 230kV. This has allowed for reduction of costs of constructing find farms. For example; cost of generating 1 MWh at the West Duddon Sands wind farm, which in 2011 amounted to 170 euro, whereas new projects are proceeding at a decreased cost to 65 euro. This record low subsidy level was achieved during the last auction round in Great Britain for power from Hornsea2 wind farm. It should be noted, for comparison, that in accordance of available date published in Great Britain cost of 1 mWh generated from coal is EUR 72 and from new build gas – EUR 70. Even if we take into account stability of supplies, there is no doubt that the cost of energy from wind is a now becoming a viable alternative for energy obtained from fossil fuels. It is also worth mentioning that the price of 1 MWh from recently approved investment for the construction of the Hinkley Point nuclear power plant has been agreed at EUR 111 for the period of 35 years.

In 2025, projected power of turbines will be on the level of 13 to 15 MW. Part of these turbines will be floating turbines, which will further reduce the capital cost of constructing offshore wind by reducing the cost of the construction of foundation for turbines, as well as reduce costs due to adverse whether delay, often incurred when building offshore wind power plants far from shore.

Constantly growing demand for electricity, shrinking resources of fossil fuels, more mature approach in care for natural environment, and very rapid development of technology make the offshore energy market very attractive. Which is why, there is a growing number of innovative, even visionary, projects that are becoming more and more realistic. A good example of such projects is the project of artificial island concept, which considered for construction in the midedle of the North Sea, and to facilitate the construction of renewable energy projects to supply 80 million people in Europe. The island concept was designed on an area of 6 km2 and is to have its own runway and a harbour. The vision is to be surrounded by fields of offshore wind turbines, but its close proximity enables construction costs to be reduced. It is proposed that this "North Sea Wind Power Hub" will transmit electricity via long-distance cables to Great Britain and the Netherlands, then to Denmark, Norway and Belgium. Network operator from the Netherlands – TenneT, has recently published a report in which it is stated that the island will be billions of euro cheaper than the conventional methods of wind farms construction.

Fig. 8. Vision of the artificial island “North Sea Wind Power Hub”.

With such an increase in Global and European demand for energy, along with the need to increase low-carbon sources in the energy mix of global economies, it is key to ensure that new energy sources are also competitive and offering value for money for the end consumers. The innovations discussed above are helping to reduce the cost of offshore energy infrastructure to meet the challenges of the energy sector now. As our country develops a stronger and more sustainable energy mix it is encouraging to see the potential benefits available, and how companies like Telefonika and JDR are leading the way with new technology and innovations to ensure the reliability of our energy supply in the future.

Bibliography: