TFEasyline MVC Medium Voltage Mobile Cable Line System

As of late, the operation of electric power lines is strongly focused on SAIDI and SAIFI indexes, which define time and duration of breaks in electric energy supply. As a consequence, in 2017, works were initiated in manufacturing plant in Bydgoszcz with the aim to design the first mobile medium voltage cable line in Poland. It is worth stressing that the idea of temporary medium voltage line had been put forward buy power engineers from Łódź division of PGE Dystrybucja.

PROPRIETARY SOLUTION

The goal of the project was to minimise break time in supply of electric energy caused by planned repairs or failures of electric power grid. It was assumed that there is a standing need for high flexibility of the temporary medium voltage cable line solution due to varied expectations of users and consumers.

QUALITY ACHIEVED

Main factors taken into account when designing the mobile medium voltage line were:

- mobility,

- versatility,

- speed of assembly,

- reliability,

- assembly and operational safety.

As an outcome, the project team created cable ‘bypass’, i.e. TFEASYLINE MVCR, which makes it possible to bypass a repaired section of overhead medium voltage electric power line with concurrent provisions for continuity of electric energy supply to consumers.

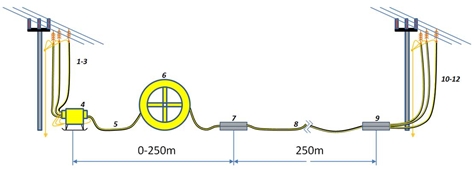

Fig. 1. Pictorial diagram of mobile cable line

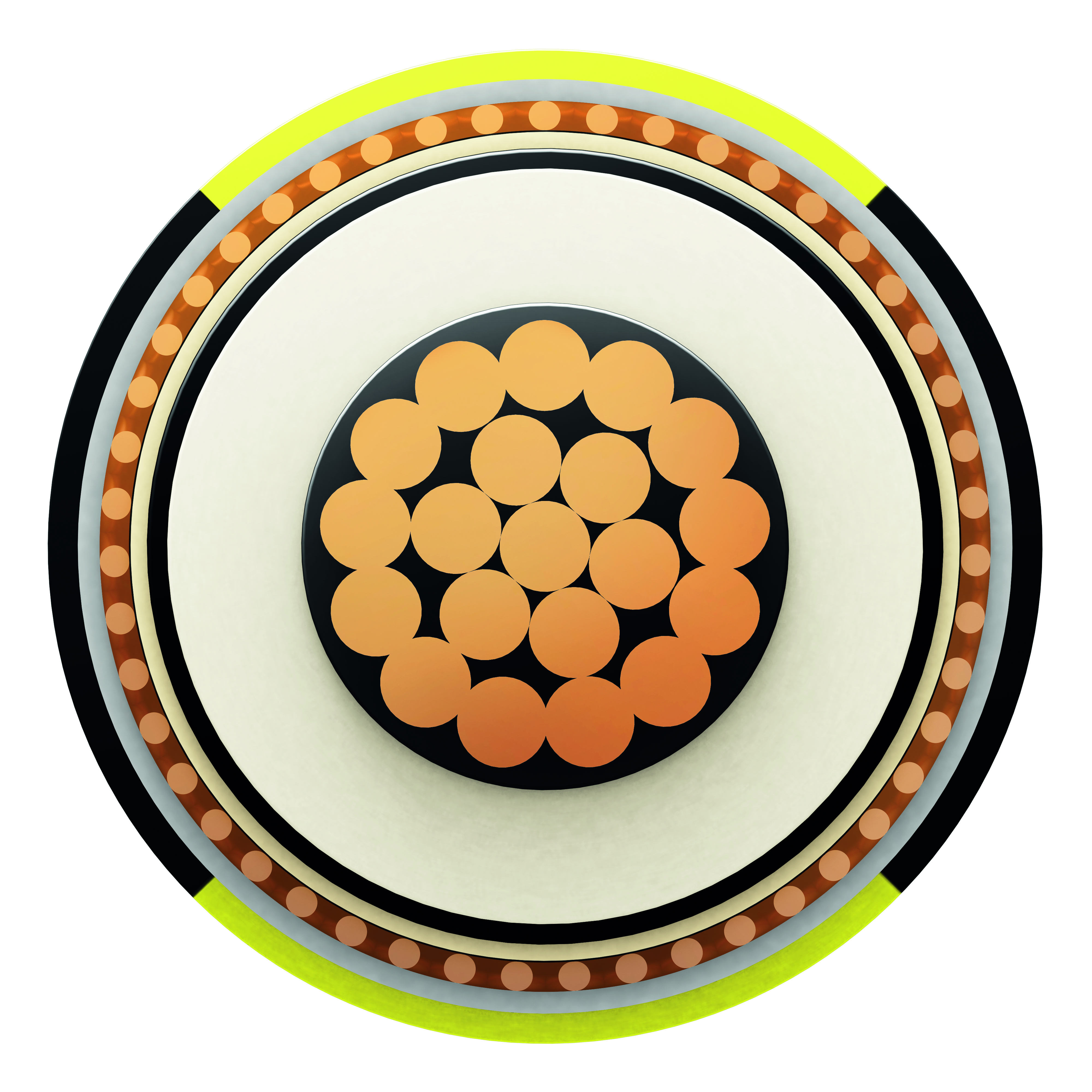

Fig. 2. Part of mobile system

The TFEASYLINE MVCR system has been equipped with two three-wire cables and nine single-wire cables, the so-called ‘cable bridges’. All three-wire cables are fitted with straight terminal connector heads, which facilitates their connection. Single-wire cables feature, on the other hand, overhead connector heads in order to directly connect them to overhead grid.

Electrical parameters of cables:

- rated voltage: 20 kV,

- operational wire cross-section: 35 mm2 / 3x35 mm2,

- metallic shield cross-section: 16 mm2 (total for three operational wires: 48 mm2 ),

- cable load capacity: 200 A.

SOLUTION MOBILE TO THE MAXIMUM

The main cable has been equipped with flexible copper wires, insulated with ethylene-propylene rubber, thus its bending radius is reduced by 50% in comparison to standard cables of the same type. This means that mobile line installation is possible indoors as well as in open spaces. The main cables features high fire resistance class, pursuant to IEC 60332-3-23, which enables its operation in areas endangered by fire.

TESTING OPTIMAL SOLUTIONS

There were 20+ and 20- voltage surges with positive results conducted, and this gave way to successful voltage test. Partial discharge test of main cable was carried out on the basis of HD 620 standard, taking into account nonstandard use. Also, bending resistance test was conducted. The line was wound and unwound repeatedly. Operational endurance is estimated for 50 windings and unwindings.

Double-core steel drums, as a fixed part of equipment, allowed for reduction in size and weight of the line. This facilitates its assembly on standard single-axis cable trolleys, irrespective of atmospheric or terrain conditions. This type of drums facilitate access to both ends of the cable, which is highly convenient in situations of fast installation of mobile line for short segments.

Fig. 5. Double-core steel drum on cable trolley

Fig. 6. TFEASYLINE MVCR line

MODULAR VERSATILITY

Modular structure of the TFEASYLINE MVCR system allows for line assembly in various configurations and its extension by any length over the distance of 250 m, depending on the extent of electrical power grid damage. All three-wire and single-wire cables are fitted with DS250 12/20kV (DE250 12/20kV) terminal connector heads, which facilitate the method of their connection, i.e. three-wire or single-wire cables are connected with main cable with CVS250 12/20kV plug-in contact connection. Additionally, all cables were designed and tested according to HD 620 S2 standard, which provides for full accommodation to regulations adopted by Polish electrical power energy grid operators.

FAST AND EASY ASSEMBLY

The single-axis trolley with own hydraulic drive, nonstandard compact steel drums, cables in HD 620 standard featuring typical equipment, protective covers for drums, connection boxes, transport cases for single-wire cable sections — this is a full equipment, assembled within no longer then 5 hours. It must be stressed that this time is short due to lack of the need to file for administrative permissions to unwind lines. Moreover, standard fixing elements have been eliminated; cable terminals are located in special polyethylene guides, which not only protect the connector heads against mechanical damages, but also allow for their easy, stable and safe connection.

.jpg)

.jpg)

Fig. 7. Connection of three-wire cables Fig. 8. Connection module

ASSEMBLY AND OPERATIONAL SAFETY

In order to increase the visibility of the line, the main cable and auxiliary elements, that is drums and connection box, feature light yellow colour and warning sign ‘UWAGA POD NAPIĘCIEM’ (CAUTION! LIVE VOLTAGE!). Moreover, the cable is reinforced with double-layer envelope, which provides for additional protection against damages. Various colours of both external envelopes cater for easy recognition of mechanical damages and prompt remedy actions.

All connections between cables are executed in special connection boxes, providing for safety of users. Cable ramps, safety barriers and warning banners compliment the mobile cable line.

ABOUT TFEASYLINE MVCR

The main aim of the project was to create a solution, which would easily and rapidly provide for continuity of electrical energy supply during planned overhauls of electrical power grids or failures. The constructed line is an outcome of cooperation between experienced engineers in cable and electrical power industry, who considered the needs and expectations of users and adopted the agenda of constant perfection of the system, connected with fitting to ever changing conditions in which the system operates.

At the end of 2018, the line was complimented with a new element, which facilitates safe line connection and disconnection in the case of safety threat situations; this is a mobile connection module, based on VCB/TEL ISM25 vacuum breaker, being the current equipment of the line.

What is important, using the cable in an unconventional way — as is the case of the mobile line — features a great challenge, calling for innovative approach and cooperation of experts and specialists. Plus, it requires running numerous test and trials in nonstandard conditions, considering the needs of users and direct customers.

It must be emphasised that it is a solution of high mobility and versatility through introduction of modular system and consideration for retention of full compatibility with standards in force and reduction of individual structural elements. This facilitates fast and easy assembly and effective operation of the system.