TELE-FONIKA KABLE S.A. is the largest producer of cables and conduits in Central and Eastern Europe. In terms of production of rubber cables, TF Kable is a leader in Poland and across Europe and the world.

TF Kable’s factory in Kraków at ul. Wielicka, has 60-years’ experience in the production of rubber cables for mining and industrial applications. We successfully deliver cables to new and existing customers around the world; mainly to mines, industrial plants, wind and solar power plants. Cables are delivered to customers in Poland and also to countries including the USA, Canada, Chile, Peru, Australia, Germany, South Africa and Ukraine, Bulgaria, Denmark, Norway, Slovakia.

TF Kable has a modern technology complex designed to compete with the world’s largest producers of rubber conduits and cables. Since June 2011, the team has worked to develop cables in rubber. The team consists of seven people who develop new modern cable structures and promote TF Kable’s products on the world markets by attending a wide variety of events, exhibitions and conferences.

TF Kable’s plant in Kraków has a rubber mixing plant which includes several modern, high performance mixers, with automatic components dosing, refrigerator and cutting machine and equipment for the automatic collection of rubber.

The whole production process of rubber mixing is strictly programmed and controlled. Due to TF Kable’s own production of electro-insulating materials on modern devices, we guarantee high quality and meetall requirements in accordance with the needs of the market.

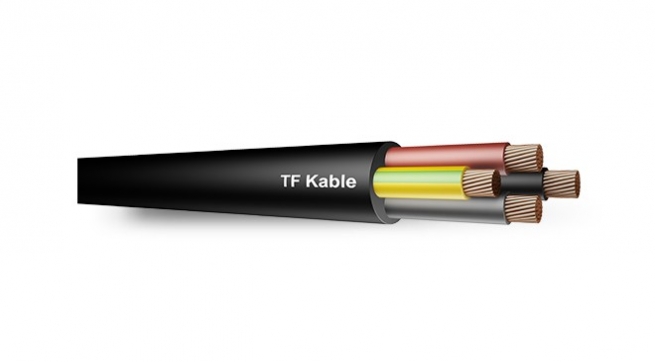

For the production of cables and conduits in rubber, TF Kable has several different lines of continuous curing, stranding machines and braiding machines. CV Lines can produce several layers of rubber in a single operation, and tooling allows continuous control of the production process and the parameters of the produced products. In addition, the plant produces mining cables in a polyurethane cover with a high resistance to abrasion. TF Kable has a very extensive production programme of cables and conduits in rubber covering rated voltages from 100/100 V to 18/30 kV, cross sections from 0.75 mm2 to 1000 mm2, and a number of cores from 1 to 56. We produce cables and conduits in accordance with Polish and foreign standards, such as DIN VDE (German), BS (British), ICEA and ASTM (American) NF C (French), SANS (South African), GOST (Russia) and many others.

Rubber used in the production of conduits and cables is based mainly on synthetic rubber such as: ethylene-propylene-dienoic acid /EPDM/, ethylene-vinyl-octane, butadiene-stirene, silicone. Rubber insulation, depending on the type and application, guarantees continuous temperature from 60°C through 110°C up to 2200°C. For the production of other elements of cables, the following rubbers are used: chloroprene, chlorinated polyethylene, chlorosulphonated polyethylene and others depending on the application.

Many-years’ experience in the production of rubber and rubber cables has enabled us to develop materials that meet a variety of requirements depending on the intended purpose of the product. Cables operating in difficult conditions such as mining have rubber tires resistant to flame spreading, tearing, crushing, grinding, water, oil and grease. The cables are constructed to ensure the longest and safest operation in difficult working conditions in underground mines and other heavy industrial conditions.